Scrappy startups: Innovators are transforming organic waste into new products

By Steve McCann | October 16, 2025

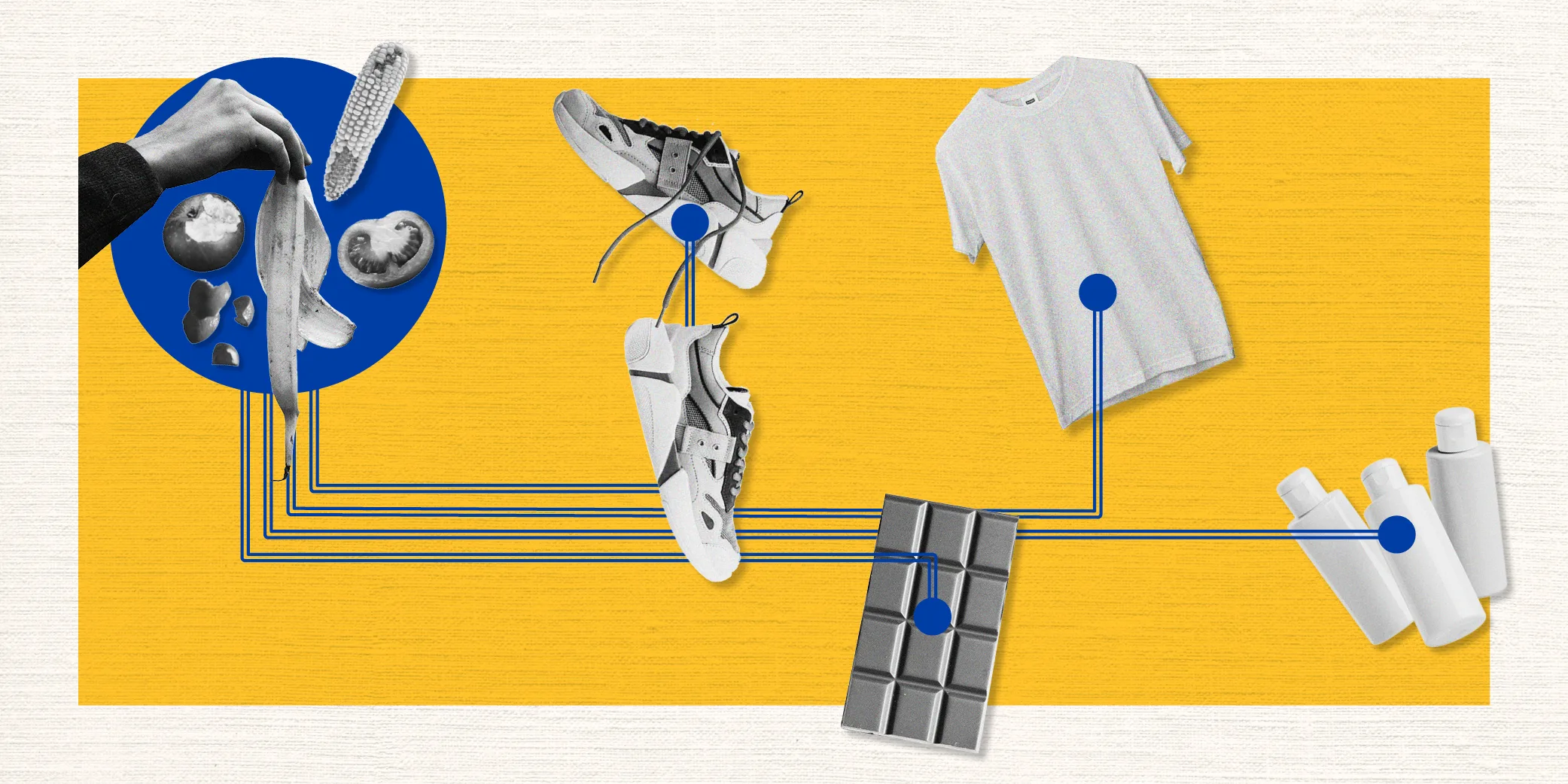

Canadian ventures are making everything from petroleum-free polyester to sweet treats.

Far too much of the crops we grow and food we produce are wasted before they ever get to our plates. According to a recent report from Second Harvest, Canada generates 21.8 million tonnes of food waste each year, 32 percent of which happens during the processing and manufacturing stage.

But the problem doesn’t end there. When organic waste winds up in landfills, it breaks down, emitting greenhouse gas emissions (GHGs), says MaRS AgTech manager Katherine Festeryga. “Food waste is one of the greatest problems plaguing the food and agriculture industry,” she says. “It accounts for 8 to 10 percent of emissions. In Canada alone, food waste generates 11 million tonnes of GHGs each year.”

But those discarded vegetable peels, fruit pits and assorted food scraps don’t have to be a large source of pollution.

More and more startups are using the manufacturing leftovers from other industries as valuable ingredients for alternative foods, clothing and household products. “We’re actually able to shift the food system from linear ‘take-make-waste’ models toward circular bioeconomies,” says Festeryga. “These innovations drive a circular, low-carbon economy that rethinks our relationship with nature while creating vast economic value.”

Here are six ventures that are turning agricultural byproducts and food waste into environmental and economic treasure.

ALT TEX is spinning food scraps into earth-friendlier fabric

What’s the deal? Globally, polyester production consumes 70 million barrels of oil each year, while a single load of laundry can release upward of 700,000 microplastic fibres. ALT TEX is fermenting fruit and veggie discards to develop a sustainable alternative.

What goes in: Food byproducts that contain sugar, such as potato skins and tomato and apple pomace, are put through a fermentation process driven by microbes and enzymes.

What comes out: A resin that can be fed into the machinery used to create conventional polyester and subsequently spun into yarn. The resulting polymer is biodegradable, but comparable to its petroleum-based counterpart in terms of strength and durability.

What’s next? This spring, ALT TEX joined SpinUp, the University of Toronto’s first wet lab incubator for startups. This partnership will help drive the company’s goal of diverting 9 kilograms of carbon emissions for every garment made with its product.

Born Maverick is developing a cruelty-free chocolate alternative

What’s the deal? The global demand for chocolate is at an all-time high — the market is currently worth U.S.$123 billion — and is expected to keep rising. But climate change, poor growing conditions and human rights problems are plaguing the industry. Belfast-based Born Maverick is working to provide a more conscientious and sustainable alternative by using date seeds instead of cacao beans.

What goes in: Born Maverick uses mycelium and precise temperature modulation to ferment date seeds into a substance that evokes the smell, taste and texture of cocoa.

What comes out: The results of that process taste like the real thing (it even contains theobromine, the nitrogen-containing compound responsible for the mood-boosting properties of chocolate), and can be used in various applications. “We don’t want to just take substrates and make it into the colour of cocoa; we want to make sure that it feels like cocoa,” says Born Maverick founder Azhar Murtuza, noting that most companies fall short of replicating the full sensory experience when they’re developing food alternatives.

What’s next? The company is developing a method to turn chicory root into an acid-resistant fibre. This will give food producers the option to add fibre to food and drink items that wouldn’t normally provide that nutritional benefit.

Dispersa is using microbes to make cleaning products

What’s the deal? To create the sudsy, soapy properties that make personal and household cleaning products effective, manufacturers have traditionally relied on palm oil and petroleum, which take a huge environmental toll. Laval, Que.–based Dispersa has found a revolutionary way to make a sustainable, biodegradable alternative — by letting microorganisms feast on food waste.

What goes in: Discarded oils and sugars are fed to bacteria and fungi; the microbial digestion process effectively serves as a form of fermentation.

What comes out: Biosurfactants — organic molecules that trap oil and grease particles. (The microbial powerhouses are separated from the final product.)

What’s next? After closing a $5.8 million seed round earlier this year, the company has begun moving into a facility that can produce 100 tonnes of product per year. Dispersa also recently signed a commercial distribution partnership to help incorporate its biosurfactants into household products.

Evoco is transforming plant waste into foam with a smaller footprint

What’s the deal? Toronto-based Evoco is using discarded plant material to make foam that can be used in footwear, furniture and other products in place of conventional options such as polyurethane — non-biodegradable materials that contain petrochemicals and can leach toxins into the environment.

What goes in: Residual oils, corn and other organic byproducts from the agriculture and forestry industries.

What comes out: Evoco’s proprietary chemical process turns those waste materials into polymers that perform on par with their petrochemical-based counterparts — with a lower carbon footprint and the ability to be composted. The company’s foams are currently being used by a number of footwear brands, Lacoste among them.

What’s next? Evoco currently holds 17 patents and is refining a plant-based leather alternative. “We don’t make anything that compromises quality or performance,” says CEO Jason Robinson.

Gaia Refinery is converting biomass for lower-energy carbon capture

What’s the deal? Although direct air capture (DAC) technology is an important strategy in achieving net-zero goals, it is also a resource-intensive process: Isolating and removing one tonne of carbon dioxide from the atmosphere uses as much as 2,500 kWh of electricity. By leveraging the energy in organic waste, Halifax-based Gaia Refinery has found a way to make DAC vastly more efficient.

What goes in: The company’s technology processes biomass — industrial residue such as wood chips, crop residues or wastewater.

What comes out: Acetic acid — effectively, exponentially concentrated white vinegar. When this acid is combined with a sorbent (the material used to trap carbon dioxide as air flows through a DAC system), the lowered pH breaks the bonds holding the captured molecules, allowing the carbon to be isolated and stored or repurposed. The process has the same effect as using electricity to catalyze a chemical reaction — without relying on massive amounts of heat.

What’s the impact? The company has begun a pilot in Hamilton that will remove 50 tonnes of carbon a year. Gaia Refinery is also preparing to launch an industrial pilot that, once it is up and running in 2027, has the potential to remove 20,000 tonnes of carbon per year.

Genecis is harnessing bacteria to make biodegradable plastic

What’s the deal? Single-use plastics are a big problem — there are currently 8,000 megatonnes of the stuff cluttering our landfills and oceans (and, ultimately, our bodies). Toronto’s Genecis is tackling this issue by using industrial waste to make biodegradable plastic products.

What goes in: Food production byproducts, such as glycerol, whey and wheat, are processed by two successive kinds of bacteria, which break down the source material into the building blocks of Genecis’s bioplastic.

What comes out: Polyhydroxyalkanoates (PHAs), used by microorganisms to store energy, which can be extracted from their microbial hosts and converted into durable, biodegradable plastic pellets.

What’s the impact? Since PHAs are still expensive and consumer packaged goods companies have razor-thin margins, Genecis has developed and commercialized its own line of compostable coffee and tea pods. “It was always going to be a stalled rollout process with B2B clients. The best way was actually to make our own products. We have way higher margins and it’s not going to break our bank,” says founder and CEO Luna Yu. “It worked out really great.”

Steve McCann

Steve McCann